autoclave check valve pdf|autoclave valves catalogue : supplier Parker Autoclave Engineers relief valves are designed to open proportionally to increasing pressure. Therefore, they are not recommended for applications requiring immediate full valve flow at set pressure and should not be considered a “Safety Valve”. Full flow of relief valve is defined as 110% of set pressure. Vacuum test, Bowie Dick test and Helix test. The following are the main mandatory autoclave tests, and details on how and when to perform them.

{plog:ftitle_list}

The effect of activated charcoal, autoclaving and culture media on sucrose hydrolysis in tissue culture media was investigated. Activated charcoal acidified an aqueous sucrose (5%) solution .

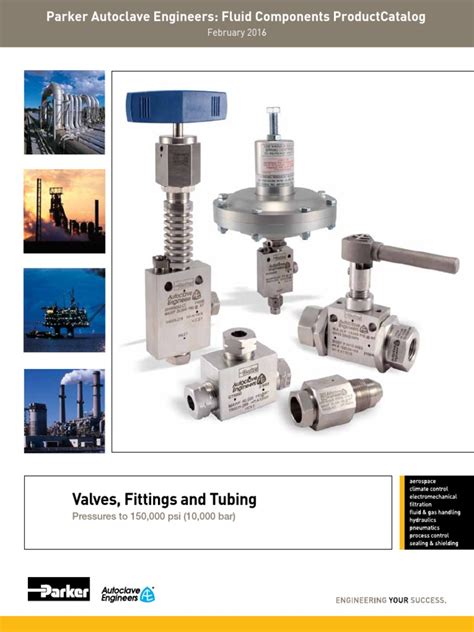

Parker Autoclave Engineers High Pressure Cone & Thread Fittings, Couplings, Filters and Valves utilize the F Style Cone & Thread Connection Detail (see Tools & Installation brochure for .Parker C Series Check Valves are designed for uni-directional flow control of fluids and gases in industries such as chemical processing, oil and gas production and transmission, .Parker Autoclave Engineers series 6DB Double Block Valve is a 2-stem ball valve combined with a separate needle valve that provides a convenient method of blocking and bleeding an .

Needle Valves: P Series (Pipe Valves) 02-1251S 1119 G - Packing Gland mounting hole drill size • G1 - Bracket mounting hole size • H* - Dimension is with stem in closed position All dimensions for reference only and subject to change • For prompt service, Parker Autoclave stocks select products. Consult factory. 2 Way StraightParker Autoclave Engineers relief valves are designed to open proportionally to increasing pressure. Therefore, they are not recommended for applications requiring immediate full valve flow at set pressure and should not be considered a “Safety Valve”. Full flow of relief valve is defined as 110% of set pressure.Standard Parker Autoclave Engineers valves with PTFE packing may be operated from 0°F (-18°C) to 450°F (232°C). High and Cryogenic temperature packing and/or extended stuffing box are available for service from -423°F (-252°C) to 1200°F (650°C) by adding the following suffixes to catalog order number:Parker Autoclave Engineers Medium Pressure fittings, nicknamed “Slimline SF”, are designed for use with SM Series valves and Parker Autoclave Engineers' Medium Pressure tubing. They incorporate coned-and-threaded connections with the orifice sized to match the high-flow 15,000 psi tubing options shown later in this brochure. For instructions

Autoclave Engineers manufactures valves, fittings and tubing for use up to 20,000 psi. View. High Pressure Valves, Fittings and Tubing Autoclave Engineers manufactures the highest quality high-pressure equipment including valves, fittings, and tubing. Autoclave's high-pressure fitting components are capable of operating to 60,000 psi.Prevent reverse flow where leak-tight shut-off is not mandatory.When differential drops below cracking pressure, valve closes. With all-metal components, valve can be used up to 1200°F (649°C).Parker Autoclave Engineers relief valves are designed to open proportionally to increasing pressure. Therefore, they are not recommended for applications requiring immediate full valve flow at set pressure and should not be considered a “Safety Valve”. Full flow of relief valve is defined as 110% of set pressure.Browse Item # CXO6600, Medium Pressure O-Ring Check Valves in the Parker / Autoclave Engineers FCD catalog including Item #,Item Name,Description,Fits Connection Type,Pressure Rating,Orifice,Rated Cv,A - Length,B - Length,C - Length,D - Ty

An autoclave is a machine that provides a physical method of sterilization by killing bacteria, viruses, and even spores using steam under pressure. . Valves and Solenoids.. (Shivaki brand) Reply. Best friend. December 10, 2021 at 2:10 AM Yes. Reply. Mannap Pirtim. September 3, 2021 at 3:09 AM Nice work. Reply. MANNAP PIRTIM. September 3 .Browse Item # CXB16, Medium Pressure Ball Check Valves in the Parker / Autoclave Engineers FCD catalog including Item #,Item Name,Description,Fits Connection Type,Pressure Rating,Orifice,Rated Cv,A - Length,B - Length,C - Length,D - Typica

Browse Medium Pressure Ball Check Valves in the Parker / Autoclave Engineers FCD catalog including Item #,Fits Connection Type,Pressure Rating,Orifice,Rated Cv. . Email This Page Download PDF Download PDF Printable Page. . Special material check valves may be supplied with four flats in place of standard hex.For dependable stem and body sealing 60VM valves feature nylon/leather packing below threads. Stem sleeve and packing gland materials have been selected to achieve extended thread cycle life and reduced handle torque. Choice of Vee or Regulating stem tips. Autoclave valves are complemented by a complete line of high pressure fittings and tubing.Standard Parker Autoclave Engineers valves with PTFE packing may be operated from 0°F (-17.8°C) to 450°F (232°C). High and Cryogenic temperature packing and/or extended stuffing box are available for service from -423°F (-252°C) to 1200°F (650°C) by adding the following suffixes to catalog order number:

Protects pressure gauges and pressure instrumentation from sudden surges in flow or venting in the event of line failure. Materials: 316 Stainless Steel: body, cover, sleeve, cover gland. 300 Series Stainless Steel: ball Vertical Installation: Since this type of check valve employs a non-spring loaded ball, valve MUST be installed in VERTICAL position with arrow on valve body .The high pressure series uses Autoclave’s coned-and-threaded connections for dependable performance in gas or liquid service. The 30VM Series valves are furnished complete with connection components, unless otherwise specified. .Browse Item # CXB24, Medium Pressure Ball Check Valves in the Parker / Autoclave Engineers FCD catalog including Item #,Item Name,Description,Fits Connection Type,Pressure Rating,Orifice,Rated Cv,A - Length,B - Length,C - Length,D - Typica

In general, an autoclave is run at a temperature of 121°C for at least 30 minutes by using saturated steam under at least 15 psi of pressure. The following are the steps to . •The safety valves are adjusted to maintain the required pressure in the chamber. •Once the water inside the chamber boils, the air-water mixture is allowed to .

For dependable stem and body sealing 60VM valves feature nylon/leather packing below threads. Stem sleeve and packing gland materials have been selected to achieve extended thread cycle life and reduced handle torque. Choice of Vee or Regulating stem tips. Autoclave valves are complemented by a complete line of high pressure fittings and tubing.For dependable stem and body sealing 60VM valves feature nylon/leather packing below threads. Stem sleeve and packing gland materials have been selected to achieve extended thread cycle life and reduced handle torque. Choice of Vee or Regulating stem tips. Autoclave valves are complemented by a complete line of high pressure fittings and tubing.

Browse Item # CB9901, High Pressure Ball Check Valves in the Parker / Autoclave Engineers FCD catalog including Item #,Item Name,Description,Fits Connection Type,Pressure Rating,Orifice,Rated Cv,A - Length,B - Length,C - Length,D - Typical

Note: Selections "F" for NPT Valves and "MF" for Medium Pressure Cone and Thread Valves are no longer included in the MPI catalog and can now be found in the Parker Autoclave Engineers Catalog: P Series NPT Valve and SM Series Valve brochures.Note: For HT and LT valves, the housing must be removed where the stem tip is larger than the body cone ring ID (SW6, SM12 and SM16 valves). Remove the housing locking device and unscrew the housing from the valve body. 5. Autoclave Engineers manual valves have three different type of stems; one piece non-rotating (figure 2), two pieceFor dependable stem and body sealing 60VM valves feature nylon/leather packing below threads. Stem sleeve and packing gland materials have been selected to achieve extended thread cycle life and reduced handle torque. Choice of Vee or Regulating stem tips. Autoclave valves are complemented by a complete line of high pressure fittings and tubing.

west nile virus elisa kit

steam penetrates the contents of autoclave the steam (moist heat) kills organisms by coagulating proteins typical temp of an autoclave is 121oC some autoclaves operate at 134oC to inactivate prions (e.g. chronic wasting disease) most contents require autoclave cycles with a minimum of 30 minutes @121oC to achieveParker Autoclave Engineers’ valves are available with piston type actuators. Five sizes of air actuators (light, mini-light, medium, heavy duty or extra heavy, single and double stage) are offered to meet the service require-ments of Parker Autoclave Engineers’ Low, Medium and High Pressure needle valves.Protects pressure gauges and pressure instrumentation from surges in flow or sudden venting in the event of line failure. Materials: 316 Stainless Steel: body, cover, sleeve, cover gland. 300 Series Stainless Steel: ball Vertical Installation: Since this type of check valve employs a non-spring loaded ball, valve MUST be installed in VERTICAL position with arrow on valve body .

The high pressure series uses Autoclave coned and threaded connections for dependable performance in gas or liquid service. The 30VM Series valves are furnished complete with connection components, unless otherwise specified. Panel mounting drill size: 0.22" all valves. All dimensions for reference only and subject to change.

parker autoclave catalog

high pressure needle valves

Stryker Precision IE 5.5mm 0 degree. For PARTS or REBUILDING.Let’s take a look at what happens inside one of these remarkable sterilizer machines. (The process is actually quite similar to the Class B tabletop autoclave, which we covered in our previous post.) Just like with a conventional oven, we first need to preheat the autoclave, so it’s nice and hot when we are ready to . See more

autoclave check valve pdf|autoclave valves catalogue